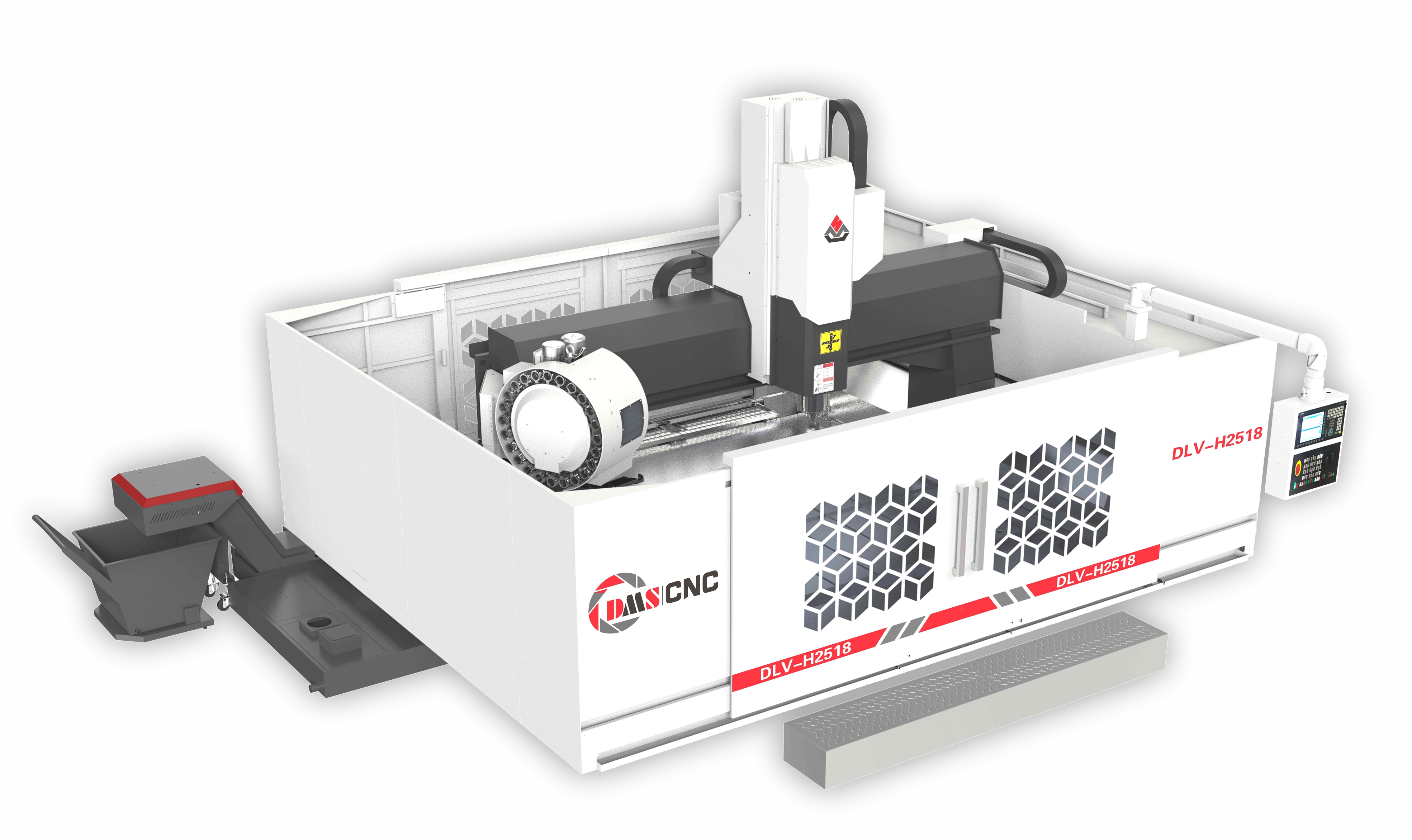

DLV-H high-speed gantry machining center

This product is developed and manufactured according to market demand, and is widely used in aerospace, new energy vehicles, machinery and equipment, rail transit, industrial profile processing, drilling, tapping and milling of aluminum alloy, steel, iron, copper and PVC and other materials , Boring orderly precision machining.

The main control parts, power parts and driving parts of the machine are all selected from world-renowned brands. The whole machine body, moving column structure, and spindle head are made of high-quality mineral cast iron. The new and reasonable structure has high strength and rigidity. The casting table can be equipped with Professional pneumatic clamps and four-axis clamps ensure that the machine runs stably, has high machining accuracy, high efficiency, and is sturdy and durable.

The innovation adopts multi-working area design, which can work in one area while loading and unloading workpieces in another area, and can also perform different processing tasks in different working areas; realize the complex processing of workpieces in one clamping. The tool magazine has 24 tool positions, which can be quickly changed according to the program requirements, and the arm can automatically change the tool; the tool is cooled by a freezing spray system or a water spray cycle, which improves the service life and the machining accuracy of the workpiece; it is equipped with an automatic chip conveyor, Adopt international advanced Fanuc, Siemens system, easy to operate, safe and convenient.

The main control parts, power parts and driving parts of the machine are all selected from world-renowned brands. The whole machine body, moving column structure, and spindle head are made of high-quality mineral cast iron. The new and reasonable structure has high strength and rigidity. The casting table can be equipped with Professional pneumatic clamps and four-axis clamps ensure that the machine runs stably, has high machining accuracy, high efficiency, and is sturdy and durable.

The innovation adopts multi-working area design, which can work in one area while loading and unloading workpieces in another area, and can also perform different processing tasks in different working areas; realize the complex processing of workpieces in one clamping. The tool magazine has 24 tool positions, which can be quickly changed according to the program requirements, and the arm can automatically change the tool; the tool is cooled by a freezing spray system or a water spray cycle, which improves the service life and the machining accuracy of the workpiece; it is equipped with an automatic chip conveyor, Adopt international advanced Fanuc, Siemens system, easy to operate, safe and convenient.

- Previous:

- No data

- Under:

- No data

Specifications

| X行程 X-Axis | 2500-13000 mm可定制其它长度) |

| Y 行程 Y-Axis | 650 mm |

| Z行程 Z-Axis | 650 mm |

| 主轴SPINDLE | |

| 主轴转速Maximum speed | 12000 rpm |

| 主轴锥孔Taper | BT40 150 mm(外径) |

| 刀库 TOOL MAGAZINE | |

| 刀库形式Type | 圆盘式 Disc type |

| 刀库容量Capacity | 24 pcs |

| 换刀时间 Automatic tool change time | 2 sec |

| 快移速度AXIS FEED RATES | |

| 移动速度Rapid onX | 60 m/min(丝杆25m/min) |

| Y/Z轴移动 Rapid onY/Z | 36/36 m/min |

| 切削进给速度 X/Y/Z cutting feed rate | 15000 mm/min |

| 操作系统OPERATION SYSTEM | FANUC SIEMENS |

| 马达功率 MOTOR POWER | |

| 主轴驱动马达Spindle driven motor | 11/18.5 KW 13/27KW |

| X/Y/Z驱动马达 X/Y/Z driven motor | 5.4 kw 3.1KW 4.5KW |

| 润滑冷却系统LUBRICATION AND COOLING SYSTEM | |

| 润滑系统Lubrication system | 自动润用 Automatic lubrication system |

| 冷却系统 Coolant system | 喷水冷却Water cooling |

| 精确度 PRECISION | |

| X定位精度 X-Axis positioning accuracy | 0.015mm |

| Y/z定位精度度Y/Z-Axls posftlonlng accuracy | 0.01 mm |

| 重复定位精度 X/Y/Z-Axls repeat positioning accuracy | 0.01 mm |

| 机械规格MECHANICAL SPECIFICATION | |

| 气压需求 Required pneumatic pressure | 0.5~0.8mpa |

| 高度 Machine height | 3400 mm |

| 占地面积 Machine covered area | 6500-13400 x 3100-3400 mm |

| 重量Machine weight | 12000-20000 kg |

400-900-8688

400-900-8688 Follow us

Follow us